Introduction

MIG welding, or Metal Inert Gas welding, is one of the most popular and versatile methods of welding used in various industries, including residential, commercial, and auto repair sectors. For those stepping into the world of welding, especially newbies eager to learn the ropes, understanding the fundamentals is crucial. Whether you're looking to pursue a career in expert welding or simply want to take on custom welding projects at home, grasping the basics can pave the way for a successful experience.

In this comprehensive guide titled "Understanding the Basics of MIG Welding for Newbies," we will delve deep into what MIG welding entails, how it compares to other types such as TIG and arc welding, essential equipment needed for mobile welding jobs, and crucial safety measures. We will also provide insights into welding certifications that can enhance your career prospects and answer frequently asked questions to round off your learning journey.

Understanding the Basics of MIG Welding for Newbies

MIG welding is a process that uses a continuous wire feed as an electrode while an inert gas protects the weld pool from contamination. This method is favored for its ease of use and high-speed capabilities. But what exactly makes MIG welding so appealing?

1. The Fundamentals of MIG Welding

MIG welding operates with three primary components:

- The Power Supply: Provides electrical energy to melt the wire. The Electrode Wire: A consumable wire that acts as both an electrode and filler material. The Shielding Gas: Usually argon or a mix of gases that protect the molten weld from atmospheric contamination.

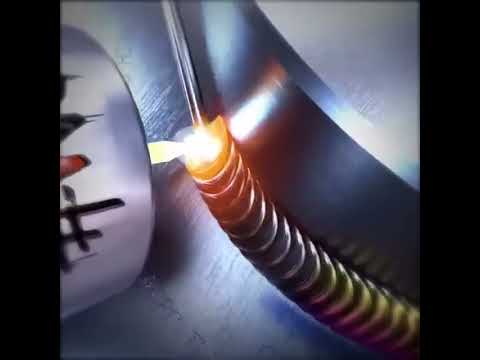

How It Works

When you initiate the arc by pulling the trigger on your MIG gun, electricity flows through the wire feeding it into a contact tip. This creates heat that melts both the wire and base metal, forming a weld pool. Meanwhile, shielding gas flows around this area, safeguarding it from oxidation.

2. Benefits of MIG Welding

- Speed and Efficiency: One of its standout features is speed; MIG welding allows for rapid joining of metals which is ideal in commercial applications. Versatility: Able to work with various materials like steel, aluminum, and stainless steel makes it suitable for different projects—from auto repair to metal fabrication. Ease of Use: Compared to other forms like TIG or arc welding, it's easier for beginners thanks to its forgiving nature.

3. Comparing MIG with Other Welding Types

MIG vs. TIG Welding

TIG (Tungsten Inert Gas) is another popular method but requires more skill due to its manual feeding technique. While TIG offers precision ideal for thin materials or intricate designs—MIG stands out in speed and ease making it better suited for larger projects.

MIG vs. Arc Welding

Arc welding utilizes electrodes xpressmobilewelding.com that are consumed during operation which can be less efficient than using a continuous wire feed in MIG processes.

Essential Equipment for MIG Welding

To get started with MIG welding effectively, you'll need specific gear:

4. The MIG Welder Machine

Choosing a quality welder machine tailored for your needs—whether residential or commercial—is vital. Ensure it's capable of handling your project's voltage requirements.

5. Protective Gear

Safety should always come first! Invest in:

- A good quality helmet with auto-darkening features Fire-resistant clothing Heavy-duty gloves

6. Consumables Required

You’ll need:

- Electrode wires (various diameters depending on your project) Shielding gas (commonly CO2 or Argon blends)

7. Workspace Setup

A clean workspace free from flammable materials is critical when performing any type of mobile or stationary welding job.

Safety Measures in MIG Welding

Welding safety cannot be overstated! Proper precautions can prevent accidents or injuries.

8. Common Hazards in Weldings

Be aware of potential hazards like:

- Fumes generated during melting metals UV radiation from arcs Electrical shocks

9. Personal Protective Equipment (PPE) Guidelines

Ensure you are wearing appropriate PPE at all times:

Use helmets with proper shade levels. Wear flame-resistant jackets. Keep gloves intact without any holes.10. Ventilation Importance

Ensure adequate ventilation when working indoors—this helps dissipate harmful fumes efficiently.

Basic Techniques in MIG Welding

Mastering basic techniques can significantly enhance your skills:

11. Setting Up Your Welder

Learning how to set voltage and wire feed speed according to material thickness is crucial before starting any project.

- Voltage Settings

Higher voltage increases penetration but may lead to burn-through if not managed correctly.

- Wire Feed Speed

Adjusting this allows you to control bead width; too fast may create inconsistent welds while too slow can lead to excessive buildup.

12. Proper Gun Angle

Maintain an angle between 10°–15° towards the direction of travel—this promotes better shielding gas coverage over your weld pool.

13: Travel Speed & Technique

Your travel speed impacts bead appearance; moving too quickly leads to undercutting while moving too slowly can cause excessive buildup—practice makes perfect!

Common Applications of MIG Welding

Knowing where you can apply your skills broadens opportunities:

14: Residential Projects

Many homeowners utilize MIG for custom fabrications like gates or fences since it's efficient yet cost-effective.

15: Commercial Applications

From manufacturing processes involving heavy machinery components to architectural structures—MIG's versatility serves numerous industries well!

16: Auto Repair

Auto body shops often favor this method due to quick repairs needed on vehicles; whether fixing frames or attaching panels—it’s advantageous across various automotive settings!

Welding Certifications: Enhancing Your Career Prospects

Whether you’re aiming for residential work or commercial applications—certifications bolster credibility within this field:

17: Why Get Certified?

Certifications demonstrate expertise which can open doors leading toward higher-paying job opportunities! Various organizations offer reputable programs focused on specific types such as MIG/TIG/Arc certifications tailored towards industry standards.

FAQs about Understanding MIG Welding

Q1: What metals can I weld using MIG?

A1: You can weld ferrous metals like mild steel & stainless steel alongside non-ferrous options such as aluminum—all depending on consumables used!

Q2: Is training required before starting?

A2: While not mandatory—it’s highly recommended! Taking courses provides hands-on experience ensuring confidence when working independently down-the-line!

Q3: Can I use my home power supply?

A3: Yes—but ensure compatibility! Home units typically handle small-scale projects only; industrial-grade ones require specialized setups often found at workshops!

Q4: How do I maintain my welder?

A4: Regularly check connections & replace worn tips; keeping equipment clean extends lifespan significantly while promoting optimal performance levels!

Q5: Are there limitations regarding thickness?

A5: Generally speaking—with adjustments—you'll find yourself able to tackle anything from thin sheet metals up until heavier stock depending on machine specs utilized!

Q6: Do I need special training beyond certifications?

A6: While certifications validate skill; practical experience gained through apprenticeships enhances overall proficiency greatly!

Conclusion

In summary, understanding the basics of MIG welding opens up numerous possibilities—from DIY residential projects to professional commercial applications and specialized fields like auto repair and metal fabrication! By familiarizing yourself with techniques, safety measures, equipment needs—and attaining relevant certifications—you'll set yourself up for success within this thriving industry landscape! So why wait? Dive right into mastering these essential skills today!

Remember—the journey begins with each spark created; embrace every opportunity provided through hands-on practice because who knows what amazing creations await just around that next corner?!